what kind of new roof for mobile like ours

Moderators: Greg, Mark, mhrAJ333, JD

Hi we have a 1973 atlanta. It is on a basement. I have only seen one other mobile built like ours. It has what I call wings 6ft additions in the front and rear of the mobile. These are not add ons they came with the mobile. We are slowly going around the home rebuilding walls and putting in new windows. We were going to do the roof last, but it has developed a leak during the last wall section we built. So my question what type of roof would be best for us to put on this trailer. Cost is a consideration. I have pictures if someone can tell me how to post them.

Hi carrot,

Welcome to the forum!

You can find instructions to upload pictures at this link in the Web Site Questions forum.

viewtopic.php?t=2414

Sort of a "27 8x10 colored glossy pictures with circles and arrows and a paragraph on the back of each one" thing. Yeah, I am old.

JD

Welcome to the forum!

You can find instructions to upload pictures at this link in the Web Site Questions forum.

viewtopic.php?t=2414

Sort of a "27 8x10 colored glossy pictures with circles and arrows and a paragraph on the back of each one" thing. Yeah, I am old.

JD

☯JD♫

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

thanks for your response on uploading pictures.

according to the instructions i think this will show my pictures

album_search.php?mode=user&search=carrot

carrot[/img]

according to the instructions i think this will show my pictures

album_search.php?mode=user&search=carrot

carrot[/img]

-

DigitalDreams

Wow amazed that your roof hasn't leaked more, it has same rolled sheeting design as my 1973 Artcraft but only about half the pitch of mine.

What we done was basically same design you probably have seen

here on forum being done on the single wides only with cap down center.

We went right over top of old roof with perlins and fanfold insulation

then used the pro steel sheets like menards sells, they are made by midwest manufacturing.

I,m assuming since yours is a 1973 same as mine it has thinner walls

but weight with the steel roofing is not a issue, as it only adds so little per square foot to the roof load its not really a issue unlike sheathing and shingles.

My county here in minnesota is really hard core on building codes and they didn't even blink a eye at this style of roof over roof.Even with a shallow pitch as long as you screw the steel down on the ridges and not the valleys it has never leaked on me.

And you don't need a lot of pitch on the steel to get rain to run off

however if you insulate before putting it on you may have to snow rake in winter like I do now cause it won't all melt off from heat loss anymore.

And as to the extensions it looks like just enough drop to them that

minor pitch from main roof side to outside would continue your off

flow in those areas.

What we done was basically same design you probably have seen

here on forum being done on the single wides only with cap down center.

We went right over top of old roof with perlins and fanfold insulation

then used the pro steel sheets like menards sells, they are made by midwest manufacturing.

I,m assuming since yours is a 1973 same as mine it has thinner walls

but weight with the steel roofing is not a issue, as it only adds so little per square foot to the roof load its not really a issue unlike sheathing and shingles.

My county here in minnesota is really hard core on building codes and they didn't even blink a eye at this style of roof over roof.Even with a shallow pitch as long as you screw the steel down on the ridges and not the valleys it has never leaked on me.

And you don't need a lot of pitch on the steel to get rain to run off

however if you insulate before putting it on you may have to snow rake in winter like I do now cause it won't all melt off from heat loss anymore.

And as to the extensions it looks like just enough drop to them that

minor pitch from main roof side to outside would continue your off

flow in those areas.

That is great that you are able to get first hand information from DigitalDreams with basically the same roof and similar weather patterns. He probably has a lot more info for you if you need it.

Looking at your roof though, I would say that it is a prime candiate for a spray foam or multi-layered elastomeric roof. These will have no problem conforming to the joints where the add-ons meet the home, especially that front area where the pitch comes down to the add-on level. You may also want to add a rubber sheet flashing to those joints to protect that area in case of major settling of the home. Any major movement would separate the roof product at that joint. That would be true of most roof products when working with add-on rooms in frost heave country.

By multi-layer elastomeric, I am not talking about a couple of coats of SnowRoof or Henry's Elastomeric. I am talking about a minimum 7-8 layers counting the roof primer and roof cloth. This will cost plenty as you will need so many coats. But this would make a roof that would last for many years and would be serviceable when the time comes. 2-3 coats put on top of that gray stuff might last a couple of years. With the multi-layer roof I am talking about, there is an excellent undercoat that will withstand ponding, and the roof fabric is what gives the new roof strength. There are probably many manufacturers of these types of products, but Conklin and Ames Research are products I am familiar with and would recommend.

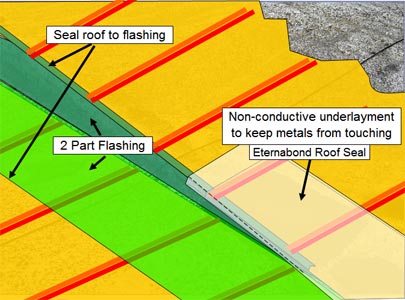

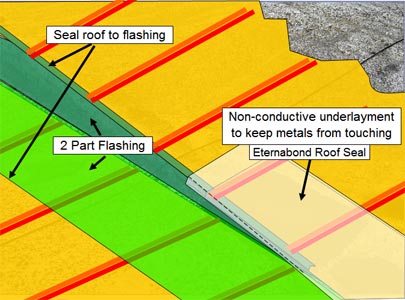

If you do go with the metal roof, I would recommend a 2-part flashing where the main coach meets the add-on rooms. Special attention would be needed in that front section where the pitch comes down to the add-on level. You would want to use some type of underlayment to keep the different sections of roof metal from touching where they will overlap. This will be protection from electro-chemical (electrolysis) from happening. Eternabond Roof Seal would be a great product for that. It is an actual finished roof product that will adhere to the old roof and be an insulator between the two metals. I made a diagram of what I am talking about. Sorry for the poor art work.

JD

Looking at your roof though, I would say that it is a prime candiate for a spray foam or multi-layered elastomeric roof. These will have no problem conforming to the joints where the add-ons meet the home, especially that front area where the pitch comes down to the add-on level. You may also want to add a rubber sheet flashing to those joints to protect that area in case of major settling of the home. Any major movement would separate the roof product at that joint. That would be true of most roof products when working with add-on rooms in frost heave country.

By multi-layer elastomeric, I am not talking about a couple of coats of SnowRoof or Henry's Elastomeric. I am talking about a minimum 7-8 layers counting the roof primer and roof cloth. This will cost plenty as you will need so many coats. But this would make a roof that would last for many years and would be serviceable when the time comes. 2-3 coats put on top of that gray stuff might last a couple of years. With the multi-layer roof I am talking about, there is an excellent undercoat that will withstand ponding, and the roof fabric is what gives the new roof strength. There are probably many manufacturers of these types of products, but Conklin and Ames Research are products I am familiar with and would recommend.

If you do go with the metal roof, I would recommend a 2-part flashing where the main coach meets the add-on rooms. Special attention would be needed in that front section where the pitch comes down to the add-on level. You would want to use some type of underlayment to keep the different sections of roof metal from touching where they will overlap. This will be protection from electro-chemical (electrolysis) from happening. Eternabond Roof Seal would be a great product for that. It is an actual finished roof product that will adhere to the old roof and be an insulator between the two metals. I made a diagram of what I am talking about. Sorry for the poor art work.

JD

☯JD♫

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

First off I can't thank you enough digitaldreams and JD for your help. We were already thinking metal roofing was the way to go it is used alot around here. Digitaldreams by chance do you have some pictures of your roof. For whatever reason I understand things alot better if I have a visual of it. Which means JD your artwork was fantastic for me to get a grip on what we need to do. Now out of curiosity have you seen mobile homes with these wings before. They are actually attached to the main mobile via hinges. Thanks again

carrot

ps We are rebuilding all exterior walls to 2x4 up form the 2x3 spliced walls. also we are redoing ceilings at the same time makeing them all 2x6 instead of 1x6. This is our home so we mostly are doing it from the inside out. I don't think I would even want to begin to have to tear the roof off.

carrot

ps We are rebuilding all exterior walls to 2x4 up form the 2x3 spliced walls. also we are redoing ceilings at the same time makeing them all 2x6 instead of 1x6. This is our home so we mostly are doing it from the inside out. I don't think I would even want to begin to have to tear the roof off.

Yes, they are quite common in my area in older homes. They called them "tip-outs" and there also some that slide out. Most of the ones I have seen only had one add-on (tip out, whatever). I don't think I have ever seen one exactly like your's though.

JD

JD

☯JD♫

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

My mobile home has had a tin roof installed but it is raised the width of 2 X 4. I really like the tin sound.

-

DigitalDreams

The post just before this one is basically how you add pitch make your

first perlin whatever you want to raise the pitch and graduate from there to about a 1 x 4 this is what I done.However if you lay down a layer of fanfold, that is the pink dow-corning styrofoam insulation which is cheap and easy to use because it just lays out as you go

you will eliminate the tinny sound from the roof unless it is hailing golf balls.

Put the fanfold down first as a insulation and noise isolator then

nail the perlins over it.

You will see in my pictures that my pitch is about triple what you have

but it was less prior, only about double yours.

I also added ladder frames on sides of house as mine had no eave,except on ends before

and this solved problems of rotting at window frames and now you can enter house in rain storm without water pouring in your face as you unlock the house,and we can leave windows open in less than driving rain and it don't pour in the sill.

I had the new end caps bent by a roofing place but the peak cap and top ends were available through same place I got the steel.

Steel has 25 or 30 year warranty I suggest best warranty type it is

slightly thicker unless you need the extra flex.

On yours you may want to have someone bend you a transition

piece from the main roof to the add ons so water in that area is

directed off main and onto secondary a little past start point.

You will see I have booted all the vents and stacks with rubber boot stacks that are for this type of steel , they work well as the metal flange around them, you use to screw them down is soft aluminum and you seal under them before screwing down.

All the soffit material was standard ,the only thing I did was use unvented soffit as no need to vent addon soffits.The fanfold and

using white steel has actually made the house cooler in summer.

Before by noon on a 90 degree day in summer it was 90 in here,now by the time inside temp reachs outside ,night is falling.

If you notice the streaking under the roofline on the soffit no this isn't from the roof,there was a field fire behind my house and then it rained the next day and that is the soot washing off the roof.[/img]

first perlin whatever you want to raise the pitch and graduate from there to about a 1 x 4 this is what I done.However if you lay down a layer of fanfold, that is the pink dow-corning styrofoam insulation which is cheap and easy to use because it just lays out as you go

you will eliminate the tinny sound from the roof unless it is hailing golf balls.

Put the fanfold down first as a insulation and noise isolator then

nail the perlins over it.

You will see in my pictures that my pitch is about triple what you have

but it was less prior, only about double yours.

I also added ladder frames on sides of house as mine had no eave,except on ends before

and this solved problems of rotting at window frames and now you can enter house in rain storm without water pouring in your face as you unlock the house,and we can leave windows open in less than driving rain and it don't pour in the sill.

I had the new end caps bent by a roofing place but the peak cap and top ends were available through same place I got the steel.

Steel has 25 or 30 year warranty I suggest best warranty type it is

slightly thicker unless you need the extra flex.

On yours you may want to have someone bend you a transition

piece from the main roof to the add ons so water in that area is

directed off main and onto secondary a little past start point.

You will see I have booted all the vents and stacks with rubber boot stacks that are for this type of steel , they work well as the metal flange around them, you use to screw them down is soft aluminum and you seal under them before screwing down.

All the soffit material was standard ,the only thing I did was use unvented soffit as no need to vent addon soffits.The fanfold and

using white steel has actually made the house cooler in summer.

Before by noon on a 90 degree day in summer it was 90 in here,now by the time inside temp reachs outside ,night is falling.

If you notice the streaking under the roofline on the soffit no this isn't from the roof,there was a field fire behind my house and then it rained the next day and that is the soot washing off the roof.[/img]

-

- Similar Topics

- Replies

- Views

- Last post

-

- 1 Replies

- 16560 Views

-

Last post by Greg

Sun May 27, 2018 8:09 pm

-

- 4 Replies

- 15402 Views

-

Last post by nestsman

Sun Apr 29, 2018 4:42 pm

-

-

How much would you pay for a paint job like this?

by CountryLiving34 » Mon Apr 02, 2018 6:57 am » in Mobile Home Repair - 1 Replies

- 19686 Views

-

Last post by Greg

Mon Apr 02, 2018 5:00 pm

-

-

-

Should windows have gaps like this??

by samantha_dahman » Thu May 28, 2020 7:11 am » in Mobile Home Repair - 3 Replies

- 27294 Views

-

Last post by samantha_dahman

Tue Jun 02, 2020 7:02 pm

-

-

- 5 Replies

- 97190 Views

-

Last post by JenniferK

Wed Nov 22, 2017 12:52 am