Onduro Corrugated roofing

Moderators: Greg, Mark, mhrAJ333, JD

-

lucasseven

I asked about trussing an old mobile before but have scrapped the idea. I'm now looking at Onduro corrugated roof system. Can any help with the following..... I have a 1979 windsor arched metal roof. I'm thinking of using the Onduro corrugated system with purlins every 16"oc. I would use 1 79" panel from each side and "cap" with another which would overlap the two side pieces by 2'. since it is arched and relatively flat I thought I would use butyl caulk on the overlaps even though on 3/12 pitch it is not needed. Has anyone done a corrugated metal or the Onduro over this type of mobile? Any help or advice would be appreciated. Thanks

I am not sure what shape your roof has. You said,

"since it is arched and relatively flat I thought I would use butyl caulk on the overlaps even though on 3/12 pitch it is not needed"

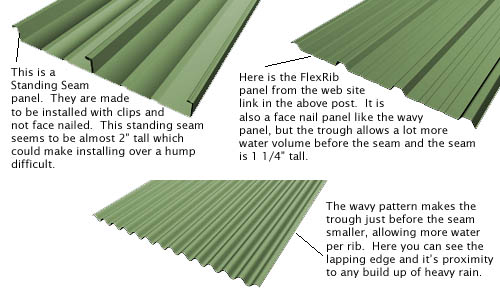

Arched and relatively flat tells me that is is a curved top roof, but 3/12 tells me that it is a gable roof with 2 flat sides. I would think that the ondura panels would work better with a gable roof than a curved top, but I would still recommend standing seam roof panels or at least the metal panels with fewer but square and wider ribs. Here is a reply to a similar question answered on the forum just before your question.

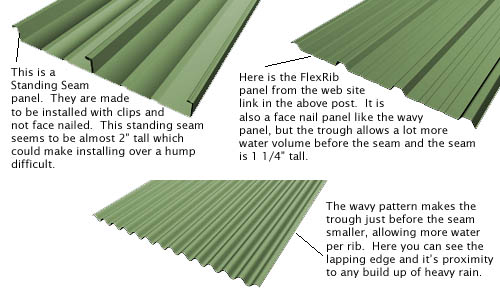

Your standard corrugated steel with the wavy pattern will have 1/2" to 7/8" ribs. Where the metal comes together, the open edge of the top sheet can create a siphoning action to allow water in the seams. This is generally not a problem for a pitched roof, because the water keeps moving. Also, these types of panels are usually face nailed with rubber grommet roof nails/screws, which can leak and need maintenance.

Quote from "Metal roof replacement?"

I'd recommend looking at Standing Seam panels. Many of these types of panels are designed to be installed without face nails. Here is a link to a website showing this type of panel. This website also has a lot of their technical drawings available, which is great for planning and ideas.

http://www.flexospan.com/metal_roofing_ ... g_seam.htm

JD

"since it is arched and relatively flat I thought I would use butyl caulk on the overlaps even though on 3/12 pitch it is not needed"

Arched and relatively flat tells me that is is a curved top roof, but 3/12 tells me that it is a gable roof with 2 flat sides. I would think that the ondura panels would work better with a gable roof than a curved top, but I would still recommend standing seam roof panels or at least the metal panels with fewer but square and wider ribs. Here is a reply to a similar question answered on the forum just before your question.

Your standard corrugated steel with the wavy pattern will have 1/2" to 7/8" ribs. Where the metal comes together, the open edge of the top sheet can create a siphoning action to allow water in the seams. This is generally not a problem for a pitched roof, because the water keeps moving. Also, these types of panels are usually face nailed with rubber grommet roof nails/screws, which can leak and need maintenance.

Quote from "Metal roof replacement?"

I'd recommend looking at Standing Seam panels. Many of these types of panels are designed to be installed without face nails. Here is a link to a website showing this type of panel. This website also has a lot of their technical drawings available, which is great for planning and ideas.

http://www.flexospan.com/metal_roofing_ ... g_seam.htm

JD

☯JD♫

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

i just did my 1977 round top mobile

i bought marks book it helped imensely

i used standard sized galvinized aluminum (painted bright white )

16 ft long pieces layed side to side on the mobile.

just remember to leave some overhang on each side

to keep water from running down the side.

16 footers gives you enough to build a soffit and fasia

search for marks book on this site it will show you enough of the pics to get a great idea for a new roof without adding very little weight.

i bought marks book it helped imensely

i used standard sized galvinized aluminum (painted bright white )

16 ft long pieces layed side to side on the mobile.

just remember to leave some overhang on each side

to keep water from running down the side.

16 footers gives you enough to build a soffit and fasia

search for marks book on this site it will show you enough of the pics to get a great idea for a new roof without adding very little weight.

im not a dr. but ill take a look

Also, I don't know what the manufacturer of these panels say, but I personally would not use a sealant on the laps of the panels. Any type of roof is going to expand and contract quite a bit. If your sealants do not hold or fail after a few years, the sealants could cause roof problems by opening up a small gap in the laps and letting water in but not letting water back out.

When I was a young man I was a pole barn builder. The barns were wood framed and used the square ribbed metal panels. No sealants were used on the laps. I will say that the rubber grommeted nails had a tendency to leak though.

JD

When I was a young man I was a pole barn builder. The barns were wood framed and used the square ribbed metal panels. No sealants were used on the laps. I will say that the rubber grommeted nails had a tendency to leak though.

JD

☯JD♫

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

-

lucasseven

Geraldk .....I was wondering what type standing seam you used? There are several types on the web link. Also do you have any pics of the job you could send me so I could see how the install looks?

Thanks for the replies

Thanks for the replies

Hey Greg,

It is just my thinking that any kind of thin sealant or even foam tape would create a little gap. If the sealant could stay stuck for the usable lifespan of the roof, then that should work. And maybe it is just our severe summer heat in my area, but I don't know of anything that I think would work for that lapped seam. Also, anyone walking on the roof for cooler maintenance, resealing of vents etc. would really flex the pans a lot when walking on them.

My concern with the standard wavy corrugated panels is the overlapping lip of the panel comes down about 1/3 the way down the overlapping ridge. If this is a 3/4" ridge, then you would have only 1/2 inch to an open seam. When it is windy and raining hard, water can be pushed up against the seam. I don't know how to spell the word, which is making my spell check worthless, but it sounds like persilic action (think siphon or venturi). Anyways, with water flowing on the open edge, this action can cause the water to keep forcing its way into the gap. This was the whole premise of the standing seam. Even a 1/2" tall standing seam will not let water in like that.

I am not saying that the wavy panels will not work. It is just from my experience, I think the other styles of panels would work better for about the same price and labor.

I am also not recommending the Flexospan product line. It was just a website that had all 3 types of panels I was talking about and has a lot of good install info. I would think that almost anyone could get panels like these locally from steel building suppliers. But if you live near Sandy Lake, PA, you might check them out.

JD

It is just my thinking that any kind of thin sealant or even foam tape would create a little gap. If the sealant could stay stuck for the usable lifespan of the roof, then that should work. And maybe it is just our severe summer heat in my area, but I don't know of anything that I think would work for that lapped seam. Also, anyone walking on the roof for cooler maintenance, resealing of vents etc. would really flex the pans a lot when walking on them.

My concern with the standard wavy corrugated panels is the overlapping lip of the panel comes down about 1/3 the way down the overlapping ridge. If this is a 3/4" ridge, then you would have only 1/2 inch to an open seam. When it is windy and raining hard, water can be pushed up against the seam. I don't know how to spell the word, which is making my spell check worthless, but it sounds like persilic action (think siphon or venturi). Anyways, with water flowing on the open edge, this action can cause the water to keep forcing its way into the gap. This was the whole premise of the standing seam. Even a 1/2" tall standing seam will not let water in like that.

I am not saying that the wavy panels will not work. It is just from my experience, I think the other styles of panels would work better for about the same price and labor.

I am also not recommending the Flexospan product line. It was just a website that had all 3 types of panels I was talking about and has a lot of good install info. I would think that almost anyone could get panels like these locally from steel building suppliers. But if you live near Sandy Lake, PA, you might check them out.

JD

☯JD♫

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Today is PERFECT!

All information and advice given is for entertainment and informational purposes only. The person doing the work is solely responsible to insure that their work complies with their local building code and OSHA safety regulations.

Hi

My 13X30 front porch roof is a standing seam aluminum roof. The panels are 12” wide. These panels are popular in Florida. I see panels with tall seams (approx 3”) and panels with a shorter seam (approx 1 ½”). My roof does not leak. These roofs are good when you have very little slope.

The siphoning action and wind forces JD describes can be a real problem.

Capillary action or wicking (the ability of water to draw more water into it) can also be the source of roof leaks especially on roofs with little slope.

I would go with JD’s suggestions.

Harry (student of roof leaks)

My 13X30 front porch roof is a standing seam aluminum roof. The panels are 12” wide. These panels are popular in Florida. I see panels with tall seams (approx 3”) and panels with a shorter seam (approx 1 ½”). My roof does not leak. These roofs are good when you have very little slope.

The siphoning action and wind forces JD describes can be a real problem.

Capillary action or wicking (the ability of water to draw more water into it) can also be the source of roof leaks especially on roofs with little slope.

I would go with JD’s suggestions.

Harry (student of roof leaks)

Aside from the roof leak, soft floors, rats, mice and bursted plumbing ........ how do you like it?

flex rib panel like the pic above is the one i used lucasseven.

29 gauge thickness minimum is what i'd recomend.

if its installed properly at the seams it wont leak.

when all the snow melts off my roof ill take a pic or two and put them in my profile .

29 gauge thickness minimum is what i'd recomend.

if its installed properly at the seams it wont leak.

when all the snow melts off my roof ill take a pic or two and put them in my profile .

im not a dr. but ill take a look

-

whty03

Is 26 gauge too heavy?

I am looking to do a roof over and I have one side recommending 29 gauge for weight and another side saying 26 gauge because 29 is thin and will wrinkle as you try to walk it over.

I am looking to do a roof over and I have one side recommending 29 gauge for weight and another side saying 26 gauge because 29 is thin and will wrinkle as you try to walk it over.

if you are doing a round top home 29gauge is suffice

26 gauge is abit better as long as it will follow the curve of the existing roof. you should only wait where the rafters are under the existing roof anyways. if ya caulk the screws as you go along and all the vents there shouldnt be any need to walk around on the roof for a few yrs.

26 gauge is abit better as long as it will follow the curve of the existing roof. you should only wait where the rafters are under the existing roof anyways. if ya caulk the screws as you go along and all the vents there shouldnt be any need to walk around on the roof for a few yrs.

im not a dr. but ill take a look

-

- Similar Topics

- Replies

- Views

- Last post

-

- 1 Replies

- 48485 Views

-

Last post by Greg

Wed Sep 27, 2017 7:46 pm

-

- 1 Replies

- 7365 Views

-

Last post by Markfothebeast

Mon May 07, 2018 1:30 pm

-

- 1 Replies

- 6963 Views

-

Last post by Greg

Wed May 23, 2018 8:15 pm