Thanks for the responses.

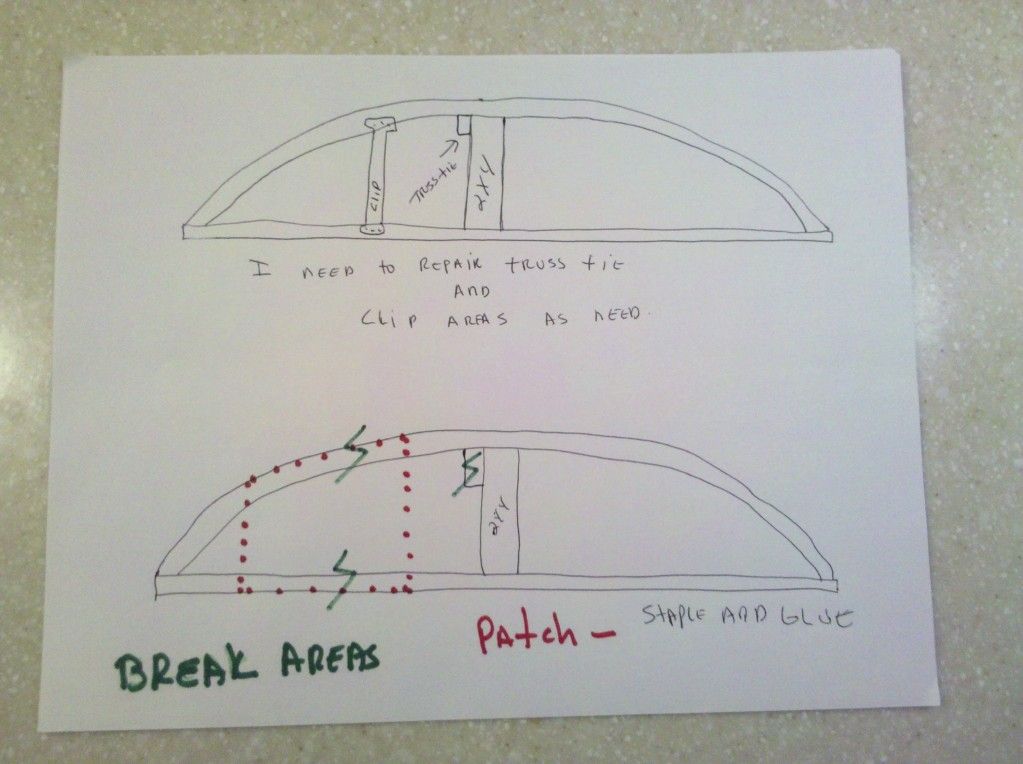

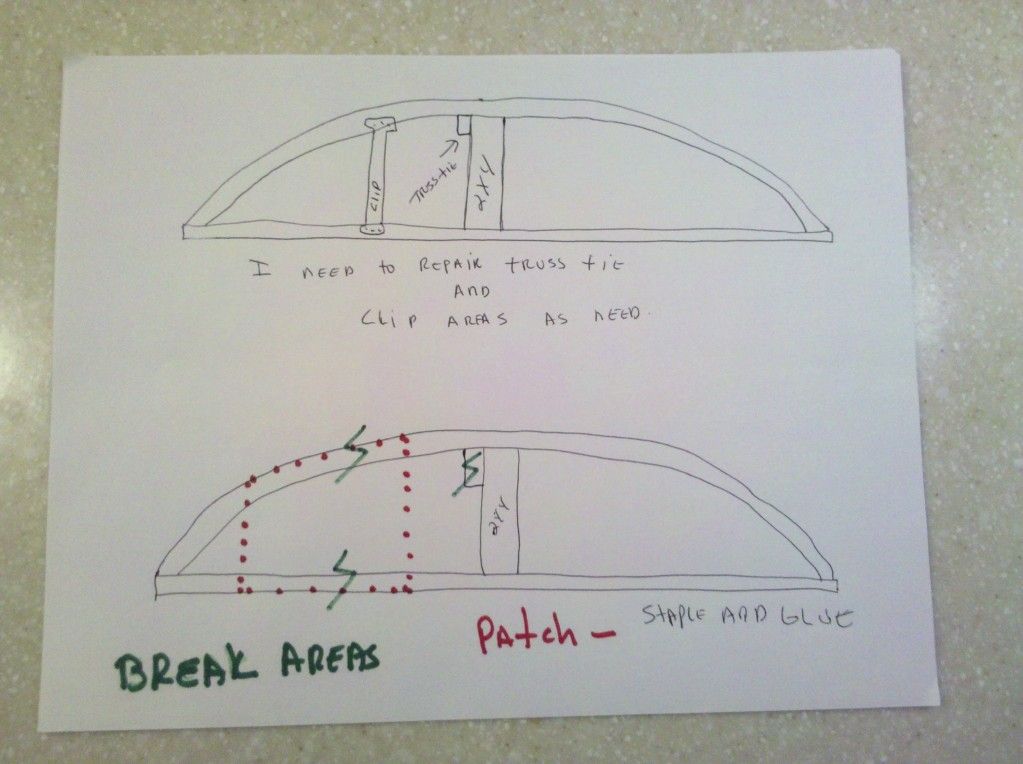

So if I understand, this is the repair procedure.

1) Take down enough ceiling tiles for access and clear all old insulation and plastic.

2) Make a template of a known good jacked up truss for repair sections.

3) Repair each truss individually

4) Jack up slightly to over correct

5) Establish correct size of patch. Pretty much half the length of the truss.

6) Push patch into place and align with lower cord. Secure with 16gauge staples and adhesive.

7)Push upper cord into place and again secure

Put patch over unbroken clip area on other end of truss for added support.

9) Drill some holes for ventilation.

10) When all is secure and dried ( Let my son be the one who walks on the roof to test it )

11) Make any roof seam repairs as needed

12) Wait for a rainy day to test

13) When good , insulate, new plastic and ceiling tiles.

14) Have a drink with buddies Jack, and Hot Damn.

Question: What size crown and leg length of 16 gauge staple ?